Oil Water Separators

Description

• Reduces coalescing media failure • Reduces pretreatment needs

• Reduces post treatment needs

• Lowers total cost of ownership

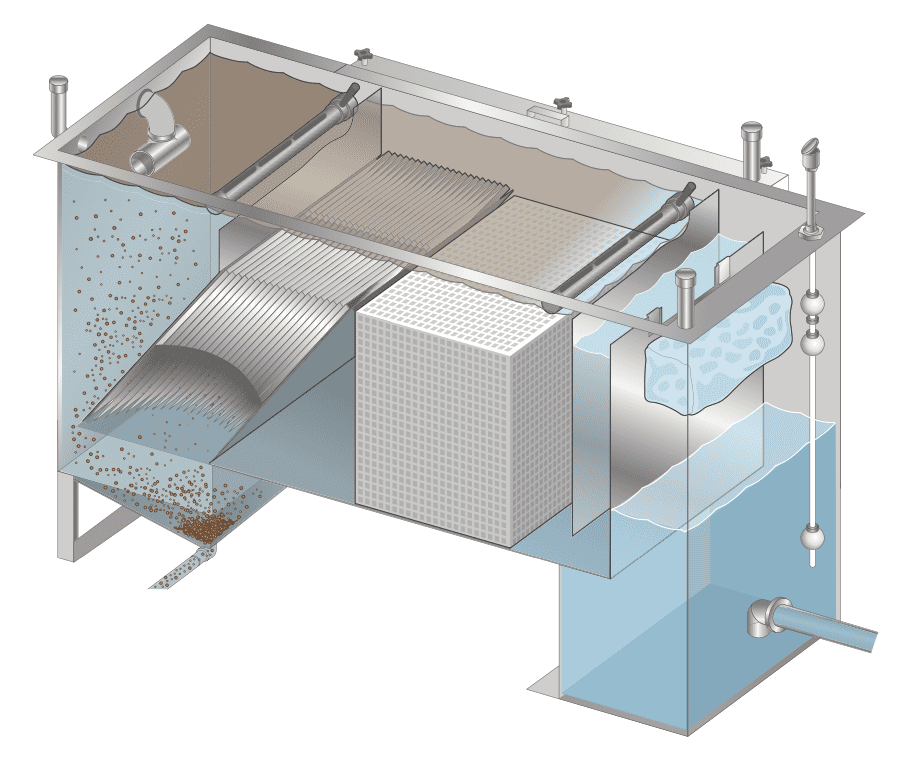

Clarification Separator is recommended for any application that has oil and a high concentration of settleable and suspended solids.

The Clarification Separator is a horizontal gravity flow pretreatment solution designed to separate settleable solids (specific gravity greater than water), suspended solids (specific gravity the same as water), and free and dispersed (non- emulsified) oil.

Units are built out of stainless steel or carbon steel. We offer several coating solutions for your specific application, such as brine water or frac water.

Our Clarification Separator, when used in conjunction with post treatment filtration, such as reverse osmosis (RO), dissolved air flotation (DAF) or electrocoagulation (EC), treats wastewater so it can be recycled or discharged.

This unit lowers the total cost of ownership of the entire water treatment system by:

- preventing large amounts of solids from entering coalescing chamber, reducing coalescing media failure.

- eliminating need of inefficient settling basins or frac tanks prior to treatment process.

- decreasing amount of carry- over entering into post treatment process.

All Reduction LLC evaporators and accessories are free standing. Installation is plug and play for a fast and easy start up.